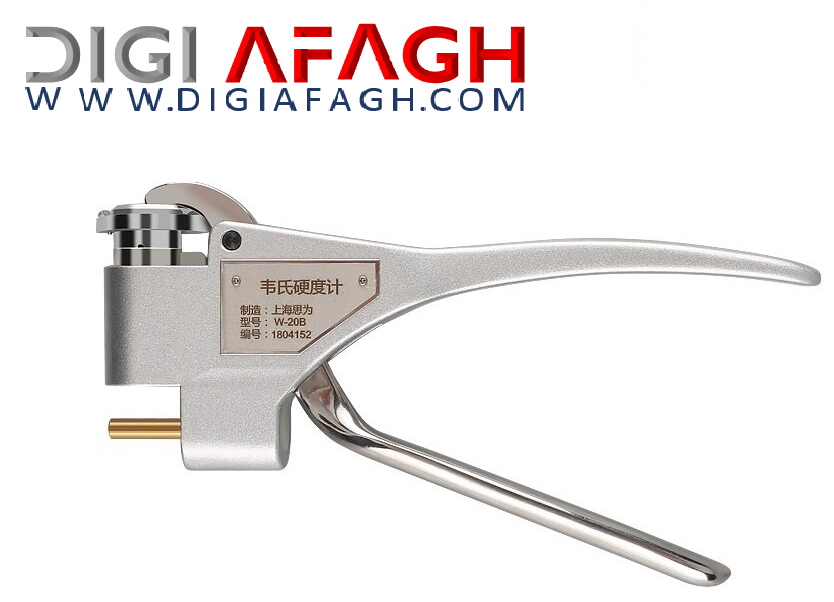

تستر Webster آلومینیومی سری MSW-20 همچنین به آن سختی سنج نوع گیره نیز گفته می شود، آنها به سه نوع MSW-20، MSW-20a، MSW-20b تقسیم می شوند، سبک و قابل حمل هستند و می توان آنها را با یک دست نگه داشت،نیازی به نمونه نیست. تست، بدون نیاز به مهارت بالا. می تواند تست NDT سریع قطعه کار را در محل انجام دهد و نیازهای کنترل کیفیت و نرخ واجد شرایط را برآورده کند. به طور گسترده در تست تولید، بازرسی پذیرش و بازرسی کیفیت محصولات صنایع آلومینیوم و بسیاری از شرکت های پنجره، درب و دیوار پرده، و همچنین در بخش بازرسی کیفیت مهندسی و نظارت فنی استفاده می شود. یک وسیله ضروری در افزایش نرخ صلاحیت و صرفه جویی در هزینه است.

Function & application

l Confirm the workpiece is heat-treated or not,

l Whether the workpiece is made of improper alloy;

l Testing over-long or over-weight workpiece;

l Project acceptance of aluminum factories

l Do project acceptance in companies of windows, door and curtain wall.

Working Principle

MW-20 series Webster hardness tester adopts indentation principle. Under pressure, the indentation is inversely proportional to the material hardness. HW is short for hardness of Webster, when the value is 16, it means the hardness is 16HW. The value can be read on the dial and can be changed into HV, HR. If the sample hardness is out of range, the needle will point at 20, if the range is too low, the needle will not move and it will stay at 0.

Working Conditions

The tester should be used in environment of clean, no vibration and no corrosive medium.

Instrument Features

l Small portable instrument, small size, light weight, one-handed operation, can quickly measure the hardness of aluminum alloy;

l Test process without sampling, can be non-destructive testing of material hardness;

l Easy to learn, no high-skill skills of the operation requirements, the human operation on the measurement results less impact, very suitable for the production site for rapid hardness testing of materials;

l There is no strict limit on the shape of the workpiece to be measured, suitable for the detection of different shapes of aluminum;

l Compared with the traditional clamp hardness tester, the digital display is more convenient to read the value, detection and display function separately, to avoid the technical staff in the field when the display device is blocked and can not read the value;

l The instrument can preset the hardness range, the quality of the workpiece to be tested, the hardness of the workpiece parts range control, improve the measurement efficiency.

Operating Method and Attentions

Operation

Put the specimen between the anvil and the indenter, press down the handle until the bottom is felt. At the time the dial indicator will point at a reading which is the hardness value. Excessive pressure beyond this limit will not damage the tester, but it is unnecessary. Hold tight the handle when reading the value. Any torsion or movement will make the reading incorrect.You can also press unit key to change into value of Hba, HR, HV, HB etc.

Measure Notes When Testing

l The use of the process should always pay attention to changes in instrument accuracy, by checking the instrument full scale point (20HW) and the calibration point is inaccurate to find inaccurate and timely correction;

l The sample surface should be perpendicular to the pressure needle, the bottom of the sample should be closely fit with the anvil, otherwise it will produce measurement error;

l The test should be applied once enough grip strength, slow afterburner will result in low measurement;

l Instrument anvil and punch with the same hardness, in addition to check the full scale value, generally do not air play, air play will wear red needle, reduce the needle life;

l Read the value of the handle should be maintained before the state of the same force until the pointer is stable and then read, read the pointer hardness value should ensure that the line of sight perpendicular to the surface of the dial to reduce the reading error;

l In the test process should avoid the sample twist, otherwise it will cause errors and damage the pointer;

l The meter head is an integrated part and can not be forcibly removed.

Instrument Maintenance

Instrument Maintenance

l Prevent contamination, use soft cloth to clean the dust or stain of the tester especially remove the contamination on the dial head or it will cause error.

l Prevent rust, when using pay special attention to its waterproof performance except clean it frequently, many parts will bear rust with water, the rust in the dial head will cause the instrument useless.

l Prevent falling off, the tester is made up of many precision components, falling off will result in permanent damage to some parts.

l Do not dismantle, all the components had already been put together properly in factory except calibration.

.svg.png)

دیدگاه خود را در مورد این کالا وارد نمایید.